Strengthening Industrial Performance

Whether a leak in a pipe or a dangerous sway of a bridge, how many structures could be improved, and failures prevented, if we had continuous visibility into them?

Current technologies offer incomplete monitoring solutions, delivering snapshot data that’s inaccurate and intermittent. With Cipher Skin’s advanced sensor technology, we can cover the entire surface of any structure, capture multiple measurements concurrently, and transmit the data wirelessly to a proprietary software. The software models movement in 3D and gives instantaneous, visualized data and diagnostics of the structure’s behavior.

Examples of

What's Possible

Through unlimited access to complete, precise data, Cipher Skin makes it possible to predict failure and enhance performance — at any time and on any structure in the physical world.

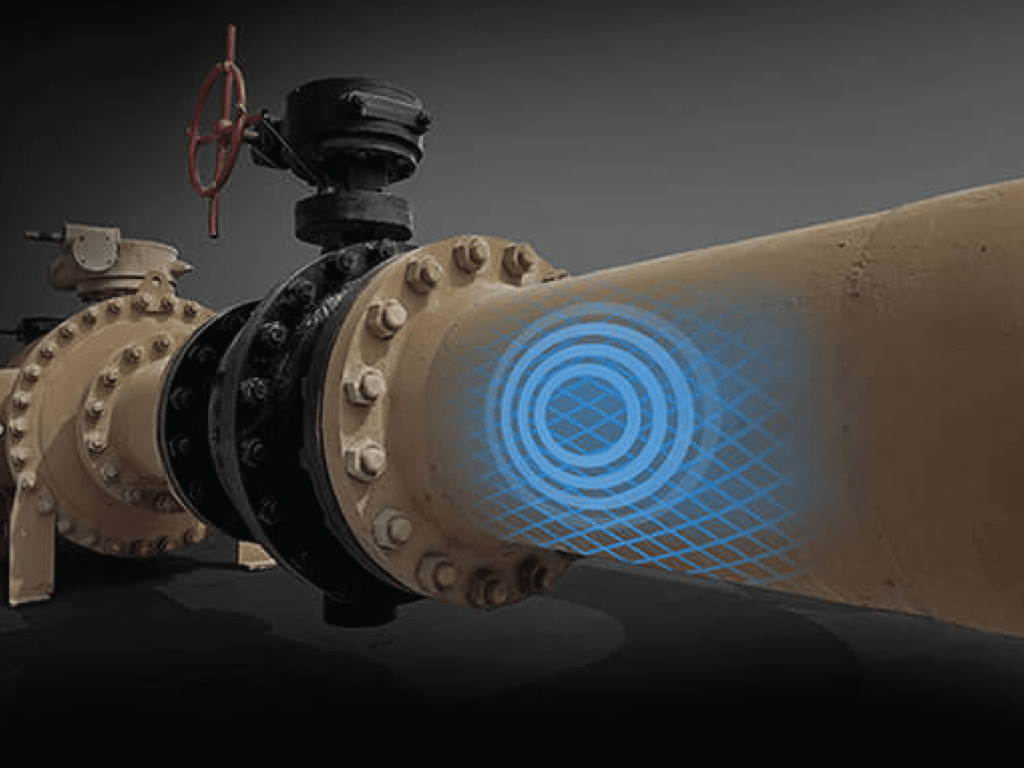

Pipes

Plants

Bridges

Hardware + Software

The Industrial Sleeve

Providing Accurate, Continuous Monitoring

We built our Industrial Sleeve with Cipher Mesh, a unique lattice construction embedded with sensors that can cover a multitude of surfaces. Printed on a conductive polymer, the Cipher Mesh powers and transmits data simultaneously through a single circuit over an entire infrastructure. Sensor integration is limitless, and its possibilities are infinite. The sleeve provides continuous monitoring for stress, strain, distortion, vibration, flow, temperature, moisture, light, and more.

The Digital Mirror

Delivering Real-Time Visualizations and Insights

The Industrial Sleeve wirelessly transmits captured data to a software application, The Digital Mirror, which models movement in 3D and delivers real-time visualizations. All data transmitted from the Cipher Mesh is collected over time, creating a rich database of the structure’s behavior. Through this database, Cipher Skin enables analyses for predictions and diagnostics, delivering valuable insights into a structure’s health and adding value for the next generation of infrastructure projects.